DuPont Crimper vs JST Crimper Comparison Best Tools for Reliable Crimps

Discover the key differences between dupont crimper and jst crimper tools plus expert tips for choosing the best crimper for reliable electronic connections

Read More

Wire Crimping Tools are essential for forming strong, reliable electrical connections.

In this guide, we’ll explain how to choose the right tool for different terminals and applications, helping you work faster and with greater confidence.

A wire crimping tools is used in electrical work to join two wires or connect a wire to a connector. These tools come in various shapes and sizes, but their core purpose is to form a secure connection.

Crimped joints are typically stronger and more flexible than soldered ones because they are mechanical rather than chemical bonds. How do you pick the right crimping tool for your project? Read on.

An electrician needs the right tool to do the job well. Using the wrong tool can cause frustration and require rework. DIY enthusiasts also benefit from a reliable wire crimping tools when building an electrical system.

There are several crimping tools on the market, but two types are most commonly used. They differ in design and application, and this guide explains them in detail. These tools are grouped by terminal type, so understanding terminals is essential first.

Wire terminals are widely used in electrical work. In Europe, wire ferrules (bootlace terminals) are particularly common. Terminal designs include ring, spade, hook, butt, bullet, pin, and more.

Pin terminals resemble wire ferrules but differ in how they are crimped. Pin terminals are intended for terminal block applications, while wire ferrules are often better for industrial uses. Wire terminals are crimped on the insulation with the central area having a diameter smaller than the wire; wire ferrules are crimped at the end with a central bore larger than the wire.

A terminal crimper is highly versatile and can crimp many kinds of wire terminals, including ring, spade, and butt terminals. It is usually labeled with AWG on the body or grip, enabling crimping across different wire gauges.

Tips: When selecting a crimping tool, consider the wire size. What is AWG? The full name of AWG is American Wire Gauge. It was introduced in 1857 to unify cable wire measurements. Generally, larger AWG numbers correspond to thinner wires. For example, 16 AWG is thinner than 10 AWG.

Take a look at the VCELINK terminal crimper, an all-in-one tool that combines cutting, stripping, and crimping. It can crimp 10-22 AWG insulated and non-insulated terminals and strip 10-24 AWG wires. It also helps cut copper, aluminum, or steel wires. This is a must-have for electrician engineers and DIY enthusiasts.

VCELINK GJ710

Features:

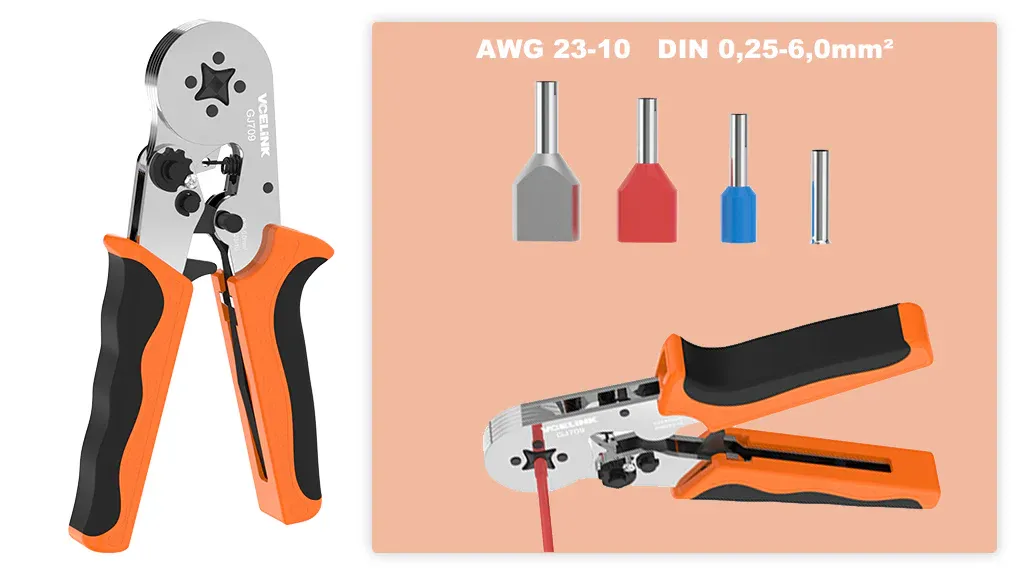

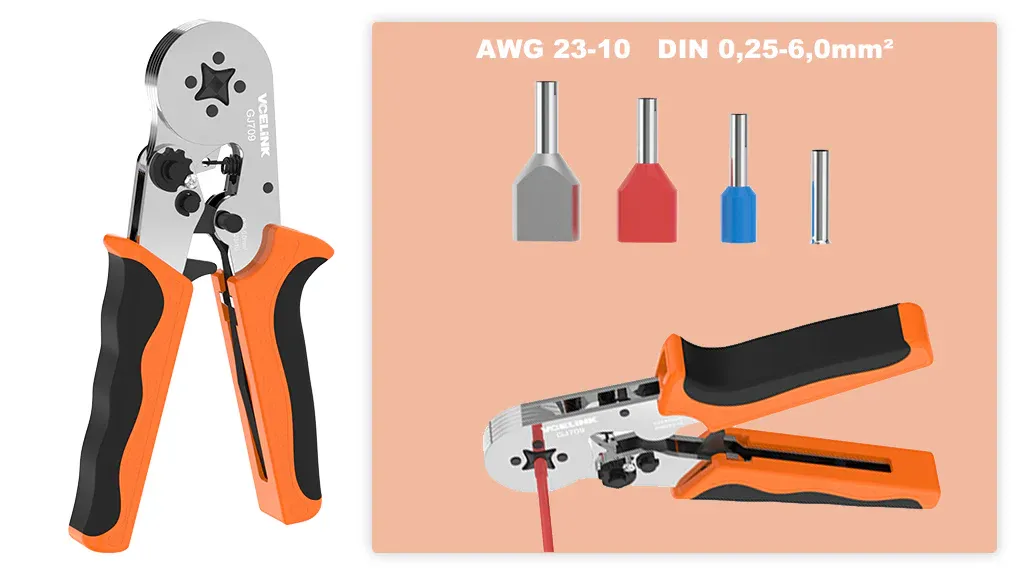

Ferrule crimpers are used to crimp stranded copper wires with ferrules. They are generally universal and can crimp various ferrules. Most ferrule crimpers look similar, with differences mainly in the crimp shape. This tool is ideal for electricians and DIYers for reliable connections in applications like car audio and speaker wiring.

VCELINK GJ709

Features:

Crimping wires is possible without a dedicated tool, but using the right crimper for each terminal type makes the process faster and more reliable. With two main crimping tool types available, you can select the one that fits your needs.

For more information, visit our blogs. While CNJPM provides general guidance for customers and visitors, it should not be considered professional advice.

Explore durable, precise tools designed for professional electricians and DIY enthusiasts.

A ferrule crimper is designed to crimp wire ferrules onto stranded wire ends, while a terminal crimper handles a variety of insulated or non-insulated terminals. Each suits different applications based on terminal type and wire gauge.

Check the tool’s specified AWG range. AWG (American Wire Gauge) numbers indicate wire thickness; larger numbers mean thinner wires. Match the tool’s range to your wire size for reliable crimps.

It’s possible with makeshift methods, but a proper Wire Crimping Tools provides consistent crimps, reduces damage risk, and saves time.

Consider compatibility with your terminal types (ring, spade, butt, ferrule, etc.), the range of wire gauges, handle comfort, and whether a self-adjusting or ratchet mechanism is preferred.

Yes. Some tools combine cutting, stripping, and crimping in one device, which can improve efficiency for frequent users.

Keep blades and dies clean, apply light lubrication to moving parts, and store in a dry environment to prevent corrosion.