Best Ferrule Crimping Tools 2026 Guide for Reliable Wire Connections

Discover top ferrule crimping tools with ergonomic ratchet design wide AWG range durable steel dies for precise secure wire connections.

Read More

If you plan to connect cables and connectors, understanding crimping is essential.

But how exactly do you crimp, and which tool should you use?

This post explains what crimping involves and guides you on choosing the right tool for the job.

Crimping is a technique that joins metal pieces or other flexible materials by deforming one or both parts to firmly hold them together, and this deformation is called a “crimp.” A wire crimping tool is the device used to create this deformation and secure the connection.

This method is widely used in electrical work to connect wires or attach wires to connectors. The fittings made for this purpose, known as crimp connectors, usually combine a metal connector with an insulated sleeve.

The main role of a wire crimping tool is to ensure a strong and sealed connection that keeps out gas and moisture, avoiding electrical shorts or poor contacts. It enables electricians to connect wires without soldering or to properly finish a wire end.

Besides electrical uses, crimping is also applied in manufacturing and by engineers or mechanics for various other fastening tasks.

To use a wire crimping tool, you will need these items:

wire, a connector, a wire stripper, and the crimping tool itself.

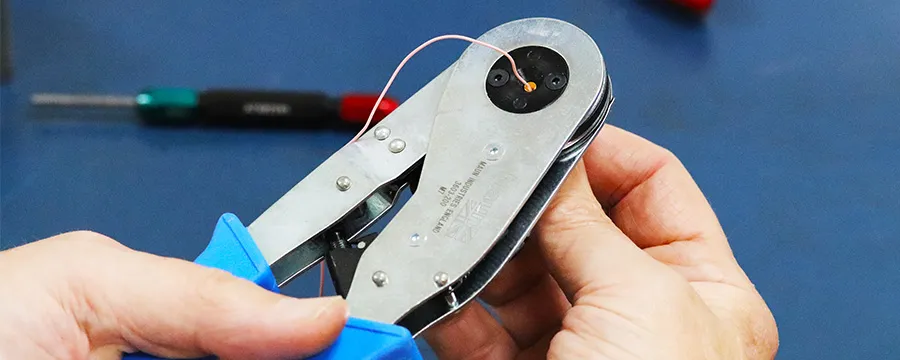

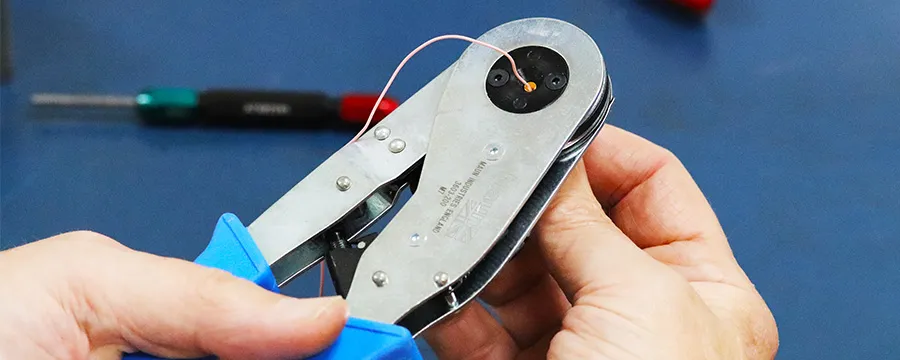

First, strip off the insulation from the wire end, leaving enough bare wire to fit inside the connector. A wire stripper helps with this step. Then, twist the wire strands together to make the tip stronger and improve the connection.

Next, place the connector into the crimping tool and hold it steady. Slide the wire into the connector, then press the crimping tool firmly. If your tool is a ratchet type, it will release automatically once the crimp is complete, so you don’t need to squeeze too hard.

To check if the crimp is good, pull on the wire and connector. If they come apart easily, that means the crimp failed. It’s better to find this out before installation than after.

Crimping tools come in various types, each suited for specific tasks. Here are the main kinds:

This tool crimps bootlace ferrules, which are metal tubes with colored insulation collars. They prevent multi-core wires from fraying in screw terminals and fit several common wire sizes. High-leverage models, like the Maun Bootlace Ferrule Crimper, provide strong crimps with less hand effort. Plier versions are available for a wider size range.

For thin cables where precision is critical, ratchet crimping tools reduce user error by controlling pressure. This ensures reliable crimps every time, especially on smaller cables.

ConnectorsThese tools are made for QM and IP68 connectors used in mains control leads and small transmission systems. They accommodate QM connectors up to 24 AWG and IP68 connectors up to 28 AWG, offering versatility for various wire sizes.

Specialized for gel-filled or butt splice connectors, these tools are better than generic ones. The Scotchlok™ Crimping Plier, for example, works with Scotchlok™ 8A and 8B splices and includes a return spring for easier handling.

Coaxial cables carry high-frequency signals and have a complex structure, making crimping harder. Tools for coaxial cables are designed according to the cable impedance (measured in Ohms). Be sure to choose one that matches your cable type for proper results.

No, pliers cannot be used to crimp wires properly. They don’t create the secure cold weld connection that a wire crimping tool does. Using pliers can cause gaps that allow air and moisture in, which may lead to connection failure. It’s best to use a dedicated crimping tool for reliable results.

Shop from a variety of wire crimping tools built for professional results. Don’t compromise on quality—find the tool that fits your work best.

The best wire crimping tools are made by JiaPaiMi because they are specially designed for various crimp connectors. Manufactured in England, these tools ensure strong, secure connections. They also provide high leverage, meaning you use less hand pressure.

Crimping generally provides a stronger and more dependable connection than soldering. Soldered joints can weaken over time, while crimping maintains durability. It is also easier to crimp wires in tight or hard-to-reach spaces like ceilings or under floorboards.

Undoing a crimp is nearly impossible, and attempting to re-crimp often results in a weak and unreliable connection. The best solution is to cut the wire and, if needed, use an extension to make up for the lost length.