DuPont Crimper vs JST Crimper Comparison Best Tools for Reliable Crimps

Discover the key differences between dupont crimper and jst crimper tools plus expert tips for choosing the best crimper for reliable electronic connections

Read More

Whether you’re a professional electrician, plumber, or a DIY enthusiast, understanding crimper tool is important. Here, we’ve gathered common questions about crimping tools, along with insights and tips from JiaPaiMi.

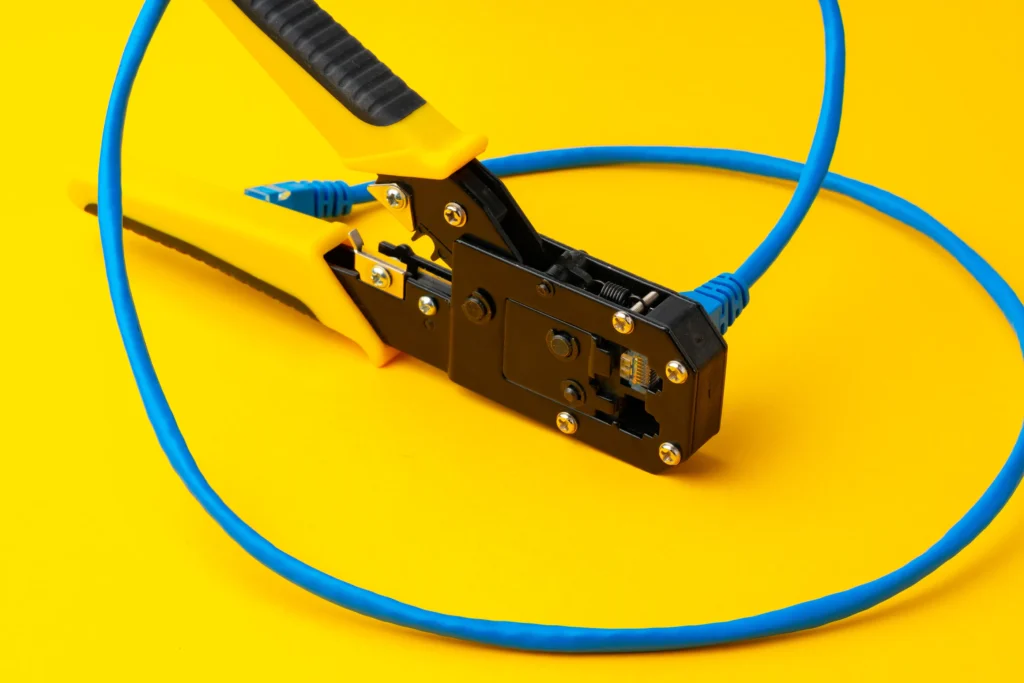

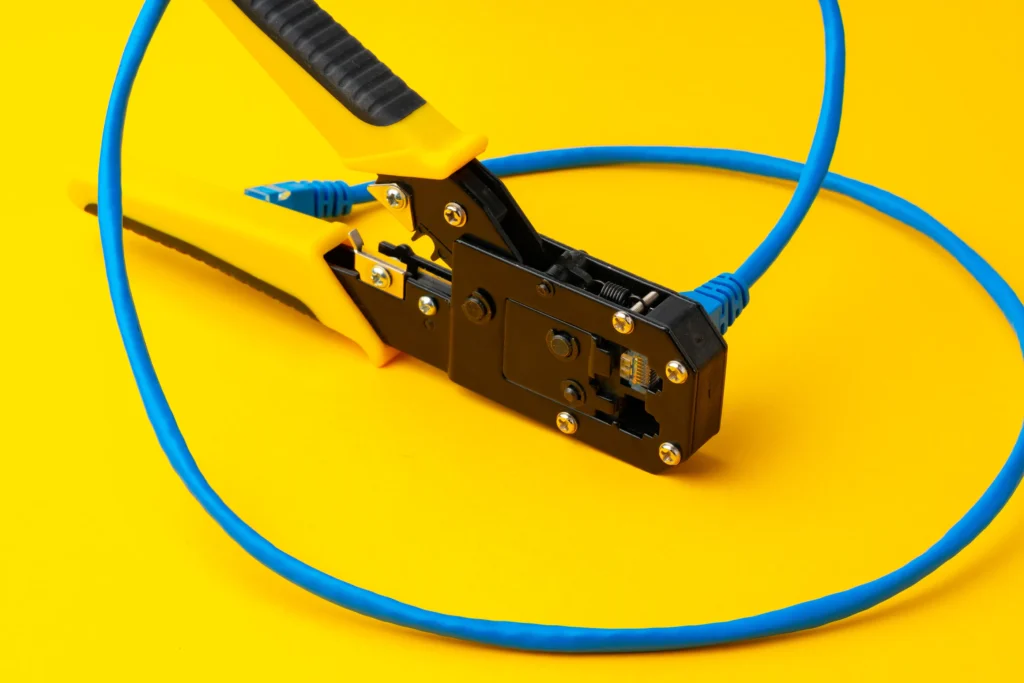

A crimper tool, like the CV Boot Clamp Crimping Pliers, is used to connect a wire or pipe to a connector by tightly pressing them together. This process shapes the materials in a way that creates a strong and leak-resistant bond. By applying pressure to a targeted spot, the crimp maintains good electrical conductivity and ensures mechanical durability.

There are various crimping tools designed for different tasks. Manual crimpers are suited for small, simple jobs. Hydraulic and pneumatic crimpers are better for more demanding, complex work. Additionally, there are specialized crimpers made for RJ45 connectors used in networking applications.

Crimping tools commonly work with materials like copper, aluminum, stainless steel, PEX tubing, and copper rings used in plumbing and electrical work. The key is that the material must be able to deform under pressure without getting damaged.

Choosing the right crimper tool depends on your specific needs, including the type of material, connector, and wire size. It’s important to know the connector’s required crimp tension and shape.

For frequent or heavy-duty use, precision tools like ratcheting or powered crimpers are recommended. Always follow the manufacturer’s guidelines to ensure proper fit and secure connections.

Yes, crimping tools are used in both electrical and plumbing work, but each field requires specialized tools. Electrical crimpers, like the HS-02C Ratchet Coaxial Cable Crimping Tool , are designed for wires and terminals. Plumbing crimpers, such as PEX crimping tools, are made specifically for pipes and fittings.

Get the SST-D PEX crimping pliers for 5/8″, 3/8″, and 1/2″ clamps. Reliable strength and smooth operation for plumbing tasks. Buy now for better efficiency!

To keep your crimper tool in good condition, regularly clean the dies to remove debris and apply lubricant to the moving parts for smooth operation. Make sure to adjust and calibrate the tool when necessary. Store it in a dry place to avoid rust, and always check for any damage before use.

Yes, crimping tools can fail or create poor connections if they are damaged, misused, or not suited for the job. Using the wrong dies, materials, or applying inconsistent pressure can result in electrical shorts, high resistance, or leaks in plumbing. Proper calibration and technique are important to avoid these issues.

In plumbing, a crimp is the action of tightly compressing a fitting or ring to secure the connection. A crimp ring is a flexible copper or stainless steel ring used to create a watertight seal during this process.

To achieve a reliable crimp, use the correct tool and die for the specific connector and wire or pipe. Position the materials properly in the tool, apply steady and even pressure, and inspect both sides of the crimp afterward. Tools like the JiaPaiMi ratchet crimper tool help maintain consistent pressure for dependable results.

Always wear safety glasses and gloves when using crimping tools. Make sure the workspace is clear of obstacles, use tools that are in good condition, and follow the manufacturer’s instructions to ensure safe operation.

A compression fitting seals a pipe by tightening a nut that presses a ferrule or ring onto the pipe. In contrast, a crimp fitting uses a crimper tool to directly squeeze the ring onto the pipe. Crimp fittings usually offer a stronger and more durable connection.

Crimped connections are generally designed to be permanent and should not be undone or reused. Attempting to repair a crimp can damage the material and cause loose, unreliable connections. For safety and reliability, it’s best to cut the wire or pipe and create a new crimp connection.

A crimping tool’s lifespan varies based on its quality, frequency of use, and maintenance. With good care, high-quality tools from JiaPaiMi can last for many years, even decades.

To keep your crimping tool in good condition, never use it for cutting or prying. Keep it clean, lubricate moving parts regularly, and store it in a dry place. Always use the correct dies and apply the right amount of pressure for each material.